Split Mountain secondary breaking drill rig,SMJR19,is a robust,single telescopic boom,self-contained diesel-hydraulic jumbo rig, with on-board water tank and air compressor for air-mist flushing.This drill rig is engineered to optimize extraction rates and safely release blockages to improve drawpoint availability in back caving operations and narrow vein mining.Split Mountain secondary breaking drill increases productivity by breaking oversized boulders without the need for explosives and time-consuming ventilation and evacuation measures.A major benefit of this breaking method is a vibration-free working environment with low dust levels, since explosives are not needed. Remote control for our secondary breaking drill rig optional,to ensure a safe working environment for the operators.

Split Mountain range of secondary breaking drills could include compact and flexible mining jumbos, longhole rigs as well as drill-charge and drill-split breaking units capable of fast, easy positioning and effective operations in confined spaces. The jumbo layout of the larger machines provides a well-protected work environment for maximum productivity, while the smallest rig offers the best accessibility and flexibility in confined spaces.

Quick Facts

» Drifter / rock drill: HC50,13kW,

» Feed 360-degree rollover and +30° / - 27°Swing,ideal for cleaning rocks on ground and hangup,

» Hole diameter: 33-51 mm with 2400mm length,

» Breaking method: drilling only,

» Engine power: 93kw/2200rpm Cummins,

Features

- Well-protected canopy/cabin for improved safety,

- Compact carrier for flexible mobility,

- No connection requirement for external power or water enables fast set up and takedown,

- High-frequency rock drill for superior productivity,

- Troubleshooting, fault finding and maintenance made easy,

- Spare part commonality across product family.

Technical Specifications

| Hydraulic Drifter/Rock Drill | Control System | ||

| Type | HC50 | Anti-jamming control | Yes |

| Percussion power | 13kW | Rotation control | Adjustable/Reversible |

| Percussion pressure | Max. 150 bar | Flushing control | Water flow and pressure |

| Percussion rate | 62Hz | Percussion control | Adjustable power |

| Rotation torque | 330 Nm | Voltage | 24V |

| Hole size (bolting) | ∅33-51 mm | Carrier | |

| Shank adapter | T38 / R32 male | Type of carrier | Frame-steered |

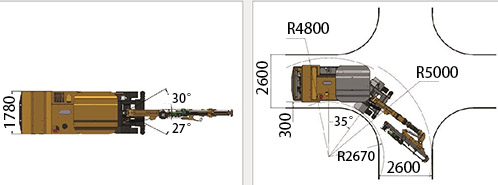

| Boom | Carrier articulation | ± 35° | |

| Parallel holding | Complete | Rear axle oscillation | ± 6° |

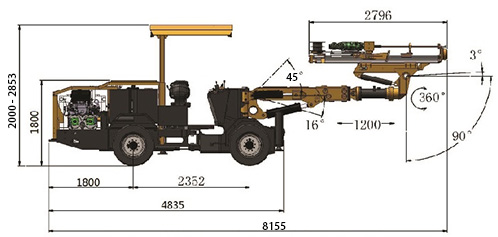

| Lifting angle | Up45°,down 16° | Cummins engine QSB-C80-31 | 93 kW,QSB3.9- C125 |

| Swing | left 30°,right 27° | Transmission Hydrodynamic | DT20000 |

| Extension | 1200 mm | Front / Rear Axles | DANA 123 |

| Feed extension | 850 mm | Tires | 11.00-20 |

| Feed roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | |

| Powerpack | 1 x 45 kW | Tramming speed | Max.16 km/h |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm |

| Filtration | 10 µ | Centralized greasing points | 10 ports |

| Oil tank volume | 200 liters | Air And Water System | |

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water |

| Electric System | Water pump capacity | 16 l/min | |

| Main switch gear | 24V | Rock drill oil consumption | 100 - 200 g/h |

| IP classification | IP65 | Rock drill air consumption | 250 l/min |

| Batteries(Chargeable) | 2 x 12 V, 90 Ah | Air compressor | 0.5 m³/min (7 bar) |

| Park lights | 2 x Red LED | Overall with bolts 1.85m,others depending on options. | |

| Parking rear brake lights | 2 x Red LED | Weight | 14000 kg |

| Search light | Manual | Transport length | 8155 mm |

| Front lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling width | 1780 mm / 2600 mm |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling height | 2000 mm / 2852 mm |

| Percussion hour meters | Optional | Turning width(T-section) | 2600 mm |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R2670 / R5000 mm |

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.