El equipo KS311 es una perforadora de una pluma diseñado para perforaciones rápidas y precisas dentro de desviaciones y túneles de secciones de 44 m².

Ventajas

Perforación eficiente al menor costo con la derivación confiable HC109.

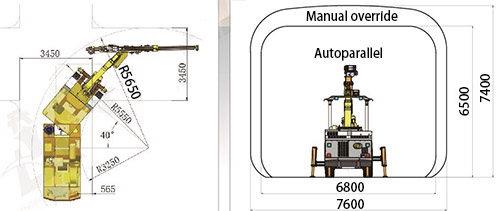

La cobertura de la pluma y varias longitudes de alimentación fijas o telescópicas ofrecen capacidades versátiles de perforación multidireccional en túneles de galerías pequeñas a medianas.

Toldo/cabina certificada con sistema de protección antiaplastamiento FOPS (Falling Object Protection System, sistema de protección antivuelco) / ROPS (Rollover Protection System, sistema de protección contra vuelcos) para una mayor seguridad de los operadores.

Chasis compacto que facilita el traslado en túneles pequeños.

La solución de problemas, la búsqueda de fallas y el mantenimiento

Datos técnicos

| Martillo de perforación | Control System | ||

| Type | HC109 | Anti-jamming control | Yes |

| Tipo de potencia | 18.8kW | Rotation control | Adjustable/Reversible |

| Percusión | 135 bar | Flushing control | Water flow and pressure |

| Tasa de percusión | 47Hz | Percussion control | Adjustable power |

| Rotation torque | 780 Nm | Voltage | 24V |

| Hole size (bolting) | ∅42-102 mm | Carrier | |

| Shank adapter | T45 / R38 male | Type of carrier | Frame-steered |

| Boom | Carrier articulation | ± 40° | |

| Parallel holding | Complete | Rear axle oscillation | ± 10° |

| Lifting angle | Up55°,down 16° | Cummins engine QSB-C80-31 | 60 kW,Tier 3 |

| Swing | left 35°,right 35° | Transmission Hydrodynamic | DT20000 |

| Extension | 1450 mm | Front / Rear Axles | DANA 123 |

| Viga extension | 1250 mm | Tires | 300-15 |

| Feed roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | |

| Powerpack | 1 x 55 kW | Tramming speed | Max.16 km/h |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm |

| Filtration | 10 µ | Centralized greasing points | 10 ports |

| Oil tank volume | 200 liters | Air And Water System | |

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water |

| Electric System | Water pump capacity | 50 l/min | |

| Standard voltages | 380 - 690 V (± 10%), 50 or 60 Hz | Rock drill oil consumption | 180 - 250 g/h |

| Total installed power | 70 kW | Rock drill air consumption | 300 l/min |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Air compressor | 0.5 m³/min (7 bar) |

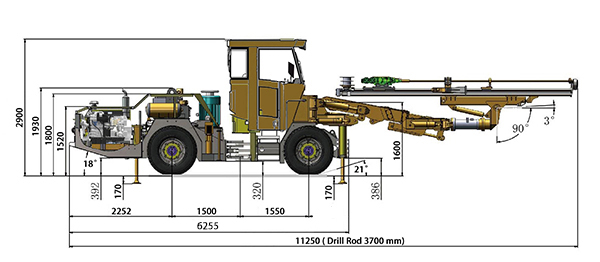

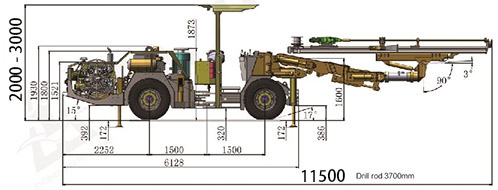

| Cable Reel | 80m-100m | Overall with steels 3.7m,others depending on options. | |

| Cable reel lubrication | Manual | Weight | 12000 kg |

| Cable reel mud clean | Manual | Transport length | 11150 mm |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / drilling width | 1750 mm / 2788 mm |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling height | 2000 mm / 3000 mm |

| Percussion hour meters | Optional | Turning width(T-section) | 3450 mm |

| Operator remote control | Optional | Radio de giro | Interno 3.250 mm, Externo 5.650 mm |

Tailor-made specifications accepted,like rock drilling process,and real-time parameters displaying through the network to achieve remote control or download.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.