- Development drill rigs

- Top hammer longhole drill rigs

- In-the-hole longhole drill rigs

- Rock support drill rigs

- Low profile rigs

- Narrow vein drill rigs

- Secondary breaking drill rigs

- Tunneling jumbos

- Underground digital offering

- Mining/Tunneling Scaler

- LHD/Load Haul Dump Loads

- Underground Mining Trucks

- Rock drill/drifters

- Boom-type Roadheader

- Air slushers

Split Mountain KJ311,is a single-boom,4-wheel drive frame-steered, electro-hydraulic mining development drill rig,for underground hard-rock mines that require very high capacity and reliability.Heavy duty boom complete parallel holding,fast and flexible positioning between holes,with HC109 or HC95LM hydraulic drifter,lowers large boulders in primary drilling,avoiding time consuming and expensive costs within drifting and tunneling of 44 m² sections.Other various options of this mining drill rig make it suitable for a range of tasks, most commonly face drilling, cross-cut drilling and bolt-hole drilling. Well-designed, robust structures and proven components ensure a reliable workplace for both operators and maintenance crews.

This development drill is available in 2 different version:

a,AMSL ≤3000m,

b,3000m ≤AMSL ≤6000m

Both ideal for 5mx5m to 6mx6m or more haulage drifts development drilling,also for exploratory / exploration / surveying drifts drilling.

Quick Facts

» Drifter / rock drill: HC109 18.8 kW,

» Feed 360-degree rollover and ±135° Swing,ideal for cross cutting and bolting,

» Hole diameter: 45-88 mm with HC109 Rock Drill/Drifter,

» Coverage: 12-44 m2,

» Engine power: 60kW/2200rpm Cummins,(a type)

» Motor power:55 kW ABB.

Features

- Boom coverage and various fixed or telescopic feed lengths offer versatile multi-directional drilling capabilities in small to medium heading drifts / tunnels,

- Compact carrier allows for tramming into small drifts / tunnels,

- FOPS/ROPS-certified cabin/canopy offers increased safety for operators,

- Troubleshooting, fault finding and maintenance made easy,

- Spare part commonality across product family.

Technical Specifications

| Hydraulic Drifter/Rock Drill | Control System | ||

| Type | HC109 | Anti-jamming control | Yes |

| Percussion power | 18.8kW | Rotation control | Adjustable/Reversible |

| Percussion pressure | Max. 135 bar | Flushing control | Water flow and pressure |

| Percussion rate | 47Hz | Percussion control | Adjustable power |

| Rotation torque | 780 Nm | Voltage | 24V |

| Hole size (bolting) | ∅42-102 mm | Carrier | |

| Shank adapter | T45 / R38 male | Type of carrier | Frame-steered |

| Boom | Carrier articulation | ± 40° | |

| Parallel holding | Complete | Rear axle oscillation | ± 10° |

| Lifting angle | Up55°,down 16° | Cummins engine QSB-C80-31 | 60 kW,Tier 3 |

| Swing | left 35°,right 35° | Transmission Hydrodynamic | DT20000 |

| Extension | 1450 mm | Front / Rear Axles | DANA 123 |

| Feed extension | 1250 mm | Tires | 300-15 |

| Feed roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | |

| Powerpack | 1 x 55 kW | Tramming speed | Max.16 km/h |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm |

| Filtration | 10 µ | Centralized greasing points | 10 ports |

| Oil tank volume | 200 liters | Air And Water System | |

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water |

| Electric System | Water pump capacity | 50 l/min | |

| Standard voltages | 380 - 690 V (± 10%), 50 or 60 Hz | Rock drill oil consumption | 180 - 250 g/h |

| Total installed power | 70 kW | Rock drill air consumption | 300 l/min |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Air compressor | 0.5 m³/min (7 bar) |

| Cable Reel | 80m-100m | Overall with steels 3.7m,others depending on options. | |

| Cable reel lubrication | Manual | Weight | 12000 kg |

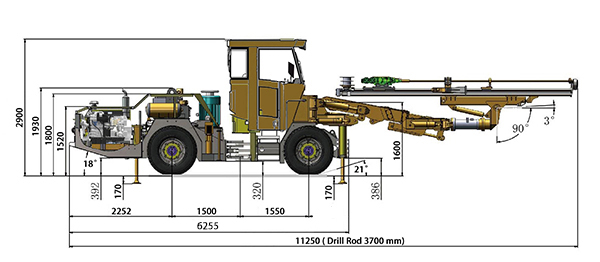

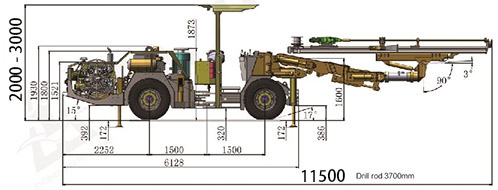

| Cable reel mud clean | Manual | Transport length | 11150 mm |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / drilling width | 1750 mm / 2788 mm |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling height | 2000 mm / 3000 mm |

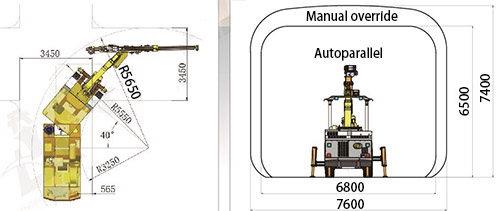

| Percussion hour meters | Optional | Turning width(T-section) | 3450 mm |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R3250 / R5700 mm |

Tailor-made specifications accepted,like rock drilling process,and real-time parameters displaying through the network to achieve remote control or download.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.