- Development drill rigs

- Top hammer longhole drill rigs

- In-the-hole longhole drill rigs

- Rock support drill rigs

- Low profile rigs

- Narrow vein drill rigs

- Secondary breaking drill rigs

- Tunneling jumbos

- Underground digital offering

- Mining/Tunneling Scaler

- LHD/Load Haul Dump Loads

- Underground Mining Trucks

- Rock drill/drifters

- Boom-type Roadheader

- Air slushers

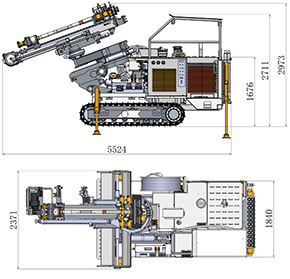

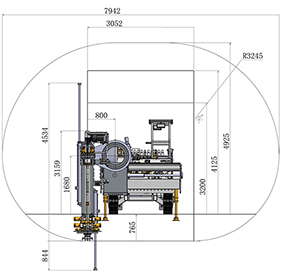

KSQ31 is a highly versatile and compact ITH in-the-hole longhole ring drill rig,designed for underground mining in 3.2 x 3.2 m medium or larger sized production drifts.This long-hole drilling rig is capable of drilling vertical,inclined fans,single and / or parallel ∅89-216 mm holes up to 100 meters in length using 3”to 8”ITH hammers,and 76 - 127 mm drill pipes in mechanized and automated underground mining operations.(For mechanized reaming slot raises,please contact us.)

Quick facts

» Hole diameter: 89-216 mm, Hole depth: 80 - 100 m (Hole diamete more than 150 mm , and / or hole depth more than 100m,please contact us),

» Cross sectional area: 4900 x 7900mm(parallel hole width 3050mm,360 degrees ring drilling),

» Engine power: 53kw/2200rpm Deutz,

» Motor power:55 kw ABB.

Features

- This drill is designed for high mobility in underground mines with ramp / raise access,

- It can be used to drill from 3 5/8″(92 mm) to 6″(150 mm) diameter holes to a depth greater than 330’(100 m) down hole. Others like for rapid raising acceptable,

- Safe roof, ROPS and FOPS cabin or canopy optional,

- Self-contained / on-board booster /compressor optional,

- Remote control optional.

Technical Specifications(Against ITH in-the-hole longhole drill rig blasting hole depth 30m with hole diameter 90-150mm)

| Top Drive | Drilling Control System | ||

| Type | SMDTHH6000 | Anti-jamming control | Yes |

| Working pressure | Up to 210 bar(rotation) | Rotation control | Adjustable/Reversible |

| Torque | Max. 5800 Nm | Flushing control | Air flow and pressure |

| Rotation speed | 0- 60 rpm | Percussion control | Adjustable power |

| Weight | 340 kg | Control panel | Grouped onboard panel |

| Length with saver sub | 760 mm | Carrier | |

| Position System | Type of carrier | Tracked carrier | |

| Rotary Acurator | 360° ring drilling | Tracks | triple grouser, sealed and lubricated |

| Sliding table | 1.5 m feed parallel positioning | Width | 305 mm / 12 in |

| Pendulum arm | 1.5 m feed parallel positioning in the side walls. | Engine - Deutz | BF4L2011 53kW |

| 1.5 m feed parallel positioning upwards/downwards | Transmission Hydrodynamic | Double-speed motor | |

| Feed dump | +20 Degrees forward | Tramming speed | Max.2.5 km/h |

| Feed drilling | -65 Degrees backward | High gear | Max.2.5 km/h |

| Drill pipe | 4' pipe | Low gear | 1.2 km/h |

| Hydraulic System | Stinger | 4 extendable | |

| Powerpack | 1 x 45 kW | Oscillation angles | +/- 6° |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 25° / 5° |

| Rotation pump | 55 cc (gear) | Ground clearance | 355 mm |

| Filtration | 10 µ | Centralized greasing points | 10 ports |

| Oil tank volume | 270 liters | Air and water System | |

| Cooler for hydraulic oil | Oil-to-air 1 x 45 kW | Flushing | By air |

| Electric System | Air capacity | 20 m3/min | |

| Standard voltages | 380 -690 V(± 10%), 50 or 60 Hz | Air pressure | 2.5 Mpa / 25 bar |

| Total installed power | 60 kW | Water booster pump | 30 l/min at 45 bar |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Hammer lubrication system | DTHHLu60 with oil level sensor |

| Cable Reel | 80m-100m | Overall with 4' pipes,others depending on options. | |

| Cable reel lubrication | Manual | Weight | 10000 kg |

| Cable reel mud clean | Manual | Transport / bolting length | 6165 mm / 5530 mm |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / bolting width | 2370 mm |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling height | 2550 mm / 2720 mm |

| Percussion hour meters | Optional | Turning width(T-section) | 2800 mm |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R2890 / R5440 mm |

Tailor-made specifications accepted.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.