- Development drill rigs

- Top hammer longhole drill rigs

- In-the-hole longhole drill rigs

- Rock support drill rigs

- Low profile rigs

- Narrow vein drill rigs

- Secondary breaking drill rigs

- Tunneling jumbos

- Underground digital offering

- Mining/Tunneling Scaler

- LHD/Load Haul Dump Loads

- Underground Mining Trucks

- Rock drill/drifters

- Boom-type Roadheader

- Air slushers

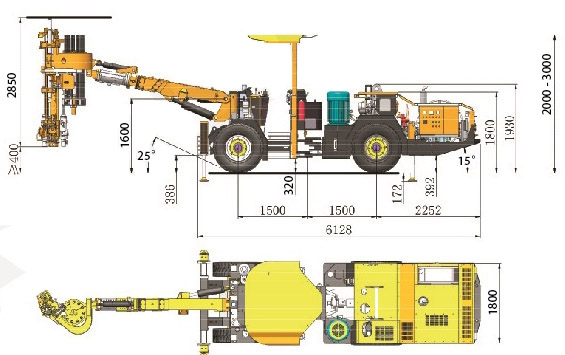

KM311 rock bolter, a fully mechanized bolting rig optimized for 5m x 5m size headings Roof support bolting and meshing. Engineered to install the most common fastening rock bolt types in roof profiles stabilizing, this roof bolting rig, in combination a screen handling arm for installation of steel wire mesh,is versatile for all rock bolting / reinforcement operations, in civil engineering, tunneling and underground mining operations.With improving safety,accurately,fast & constant positioning,drilling and bolting,the drilling rig increases your productivity while lowering your operating costs.

An open service arichitecture,maked this rock bolting rig easy maintenance and service.

Features

» Designed for roof reinforcement in underground mines with small and medium cross sections as small as to 2.5*4 m(W*H)

» Easy to Drill and Bolt Vertical,inclined 3m depth Bolting holes at 5m height roof

» Install several rows of 1.5–3-meter (5–10ft) rockbolts from a single set-up

» Length of bolts 5',6',7',8'and 10'

» Well-proven bolting head with reliable parts

» The rock bolting process is completely mechanized and controlled by a single operator from under a ROPS/FOPS safety cabin or FOPS safety canopy

» Produtivity up to 7800 bolts/month

Technical Specifications

| Hydraulic Drifter/Rock Drill | Control System | |||

| Type | HC50(Drilling) | HC50(Bolting) | Anti-jamming control | Yes |

| Percussion power | 13kW | Rotation control | Adjustable/Reversible | |

| Percussion pressure | Max. 150 bar | Flushing control | Water flow and pressure | |

| Percussion rate | 62Hz | Percussion control | Adjustable power | |

| Rotation torque | 330 Nm | Voltage | 24V | |

| Hole size (bolting) | ∅32 - 51 mm | Carrier | ||

| Shank adapter | 45 mm / R32 male | Type of carrier | Frame-steered | |

| Bolting Head | Carrier articulation | ± 35° | ||

| Bolt carousel capacity | 10 rock bolts with 200 x 200 mm Max. plate size | Rear axle oscillation | ± 10° | |

| Deutz engine BF4L914 | 73 kW,air cooled Tier 3 | |||

| Bolt head length | Max. 4150 mm | Transmission Hydrodynamic | DT12000 | |

| Bolting Boom | Front / Rear Axles | DANA 123 | ||

| Boom extension | 1200 mm | Tires | 12.00-20 | |

| Roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc | |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | ||

| Powerpack | 1 x 55 kW | Tramming speed | Max.16 km/h | |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° | |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm | |

| Filtration | 10 µ | Centralized greasing points | 10 ports | |

| Oil tank volume | 200 liters | Air And Water System | ||

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water | |

| Electric System | Water pump capacity | 50 l/min | ||

| Standard voltages | 380 - 690 V (± 10%), 50 or 60 Hz | Rock drill oil consumption | 100 - 200 g/h | |

| Total installed power | 70 kW | Rock drill air consumption | 150 - 250 l/min | |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Air compressor | 1 m³/min (7 bar) | |

| Cable Reel | 80m-100m | Overall with bolts 1.5m,others depending on options. | ||

| Cable reel lubrication | Manual | Weight | 12900 kg | |

| Cable reel mud clean | Manual | Transport / bolting length | 10500 mm / 9650 mm | |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / bolting width | 1800 mm / 3100 mm | |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / bolting height | 2000 mm / 3300 mm | |

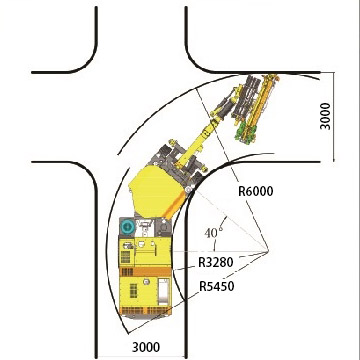

| Percussion hour meters | Optional | Turning width(T-section) | 3000 mm | |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R3280 / R6000 mm | |

Tailor-made specifications accepted.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.