- Development drill rigs

- Top hammer longhole drill rigs

- In-the-hole longhole drill rigs

- Rock support drill rigs

- Low profile rigs

- Narrow vein drill rigs

- Secondary breaking drill rigs

- Tunneling jumbos

- Underground digital offering

- Mining/Tunneling Scaler

- LHD/Load Haul Dump Loads

- Underground Mining Trucks

- Rock drill/drifters

- Boom-type Roadheader

- Air slushers

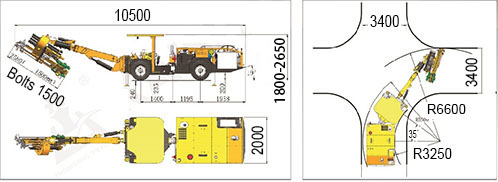

KM211 rock bolter,is a compact and highly versatile electro-hydraulic rock support drill rig,diesel tramming and electric drilling,compact carrier,efficient and durable rock bolt integrity making it the versatile rock support drill rig which can be used for both rehabilitation rock reinforcement and roof reinforcement in production areas or in underground mines or tunnels with small and medium cross sections.

Features

» Designed for underground hard-rock mines, offers a good performance-to-cost ratio for 2.7x2.7-meter drifts, gives you tools to increase your productivity, improve safety and lower your operating costs with reliability,

» Past cross sections as small as to 2.5*1.7 m(W*H)

» Easy to Drill and Bolt Vertical,inclined 2.2m depth Bolting holes at 2.8m height roof

» Install several rows of 1.5–3-meter (5–10ft) rockbolts from a single set-up

» Length of bolts 5',6',7',8'and 10' (Type of split set, resin & cement cartridge rebar, Swellex, Hydrabolt .)

» Well-proven bolting head with reliable parts

» The rock bolting process is completely mechanized and controlled by a single operator from under a ROPS/FOPS safety cabin or FOPS safety canopy

» Produtivity up to 7000 bolts/month

Technical Specifications

| Hydraulic Drifter/Rock Drill | Control System | |||

| Type | HC50(Drilling) | HC50(Bolting) | Anti-jamming control | Yes |

| Percussion power | 13kW | Rotation control | Adjustable/Reversible | |

| Percussion pressure | Max. 150 bar | Flushing control | Water flow and pressure | |

| Percussion rate | 62Hz | Percussion control | Adjustable power | |

| Rotation torque | 330 Nm | Voltage | 24V | |

| Hole size (bolting) | ∅ 32 - 51 mm | Carrier | ||

| Shank adapter | 45 mm / R32 male | Type of carrier | Frame-steered | |

| Bolting Head | Carrier articulation | ± 35° | ||

| Bolt carousel capacity | 8 rock bolts with 150 x 150 mm Max. plate size | Rear axle oscillation | ± 10° | |

| Deutz engine BF4L914 | 73 kW,air cooled Tier 3 | |||

| Bolt head length | Max. 4150 mm | Transmission Hydrodynamic | DT20000 | |

| Bolting Boom | Front / Rear Axles | DANA 123 | ||

| Boom extension | 1200 mm | Tires | 12.00-20 | |

| Roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc | |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | ||

| Powerpack | 1 x 55 kW | Tramming speed | Max.16 km/h | |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° | |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm | |

| Filtration | 10 µ | Centralized greasing points | 10 ports | |

| Oil tank volume | 200 liters | Air And Water System | ||

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water | |

| Electric System | Water pump capacity | 50 l/min | ||

| Standard voltages | 380 - 690 V (± 10%), 50 or 60 Hz | Rock drill oil consumption | 100 - 200 g/h | |

| Total installed power | 70 kW | Rock drill air consumption | 150 - 250 l/min | |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Air compressor | 1 m³/min (7 bar) | |

| Cable Reel | 80m-100m | Overall with bolts 1.5m,others depending on options. | ||

| Cable reel lubrication | Manual | Weight | 15000 kg | |

| Cable reel mud clean | Manual | Transport / bolting length | 10500 mm / 9900 mm | |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / bolting width | 2000 mm / 3300 mm | |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / bolting height | 1650 mm / 2600 mm | |

| Percussion hour meters | Optional | Turning width(T-section) | 3400 mm | |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R3250 / R6600 mm | |

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.