- Development drill rigs

- Top hammer longhole drill rigs

- In-the-hole longhole drill rigs

- Rock support drill rigs

- Low profile rigs

- Narrow vein drill rigs

- Secondary breaking drill rigs

- Tunneling jumbos

- Underground digital offering

- Mining/Tunneling Scaler

- LHD/Load Haul Dump Loads

- Underground Mining Trucks

- Rock drill/drifters

- Boom-type Roadheader

- Air slushers

KJ313 is a top mounted telescopic feed, single boom development / production jumbo drill rig, with good covering ability,nearly no left areas for second drilling.This jumbo drill's telescopic feeds are lightweight,durable and cost effective, featuring aluminum drill cradles, lasting components,as well as drill-specific steel drill mounts(to prevent wear to the aluminum cradles),increasing your uptime and reducing your operating costs. Auto return are mounted to the drill cradles to allow for various drill depth settings corresponding to a variety of collapsible configurations for drill rods including 6 ft – 10 ft, 8 ft – 12 ft, 10 ft – 14 ft, increasing productivity with improving drifter accuracy,performance and reliability.

This telescopic feed production jumbo drill rig customizable with several different options including hydraulic centralizer and heavy-duty feed cylinder for probe drilling.

Quick Facts

» Drifter / rock drill: HC109 18.8 kW, HC95LM 21kW optional,

» Stinger Assembly helps stabilize the drill steel when drilling,

» Feed 360-degree rollover and ±135° Swing,ideal for cross cutting and bolting,

» Bulkhead is designed to eliminate the requirement to replace full length hydraulic hoses if damaged,

» Hose Drum Assembly incorporate grooves to help maintain hose alignment,

» Footer Adapter is fastened to the bottom of the feed rail to eliminate wear to the feed beam and Boom Cradles are used to mount to Jumbo Boom Tables,

» Hole diameter: 45-102 mm with HC109 Rock Drill/Drifter,

» Coverage: 12-50 m2,

» Engine power: 62kw/2200rpm Deutz,

» Motor power:55 kw ABB.

Features

- Drills both support and face advance, optimizing the mining cycle,

- Short telescopic feed ensure access to confined areas,

- FOPS/ROPS-certified cabin/canopy offers increased safety for operators,

- Troubleshooting, fault finding and maintenance made easy,

- Spare part commonality across product family.

Technical Specifications

| Hydraulic Drifter/Rock Drill | Control System | ||

| Type | HC109 | Anti-jamming control | Yes |

| Percussion power | 18.8kW | Rotation control | Adjustable/Reversible |

| Percussion pressure | Max. 135 bar | Flushing control | Water flow and pressure |

| Percussion rate | 47Hz | Percussion control | Adjustable power |

| Rotation torque | 780 Nm | Voltage | 24V |

| Hole size (bolting) | ∅42-102 mm | Carrier | |

| Shank adapter | T45 / R38 male | Type of carrier | Frame-steered |

| Boom | Carrier articulation | ± 35° | |

| Parallel holding | Complete | Rear axle oscillation | ± 6° |

| Lifting angle | Up55°,down 16° | Deutz engine F5L912W | 62 kW |

| Swing | left 35°,right 35° | Transmission Hydrodynamic | DT20000 |

| Extension | 1450 mm | Front / Rear Axles | DANA 123 |

| Feed extension | 1250 mm | Tires | 11.00-20 |

| Feed roll-over angle | 360° Rotaty Actuator | Service brakes | Hydraulic wet disc |

| Hydraulic System | Parking and emergency brakes | SAHR fail safewet disc | |

| Powerpack | 1 x 55 kW | Tramming speed | Max.16 km/h |

| Percussion pump | 100 cc (variable) | Gradeability / sideways tilt | Max. 15° / 5° |

| Rotation pump | 45 cc (gear) | Ground clearance | 320 mm |

| Filtration | 10 µ | Centralized greasing points | 10 ports |

| Oil tank volume | 200 liters | Air And Water System | |

| Cooler for hydraulic oil | Oil-to-water 1 x 30 kW | Flushing | By water |

| Electric System | Water pump capacity | 50 l/min | |

| Standard voltages | 380-690V(±10%),50/60Hz | Rock drill oil consumption | 180 - 250 g/h |

| Total installed power | 70 kW | Rock drill air consumption | 300 l/min |

| Batteries(Chargeable) | 2 x 12 V, 80 Ah | Air compressor | 0.5 m³/min (7 bar) |

| Cable Reel | 80m-100m | Overall with steels 3.7m,others depending on options. | |

| Cable reel lubrication | Manual | Weight | 12000 kg |

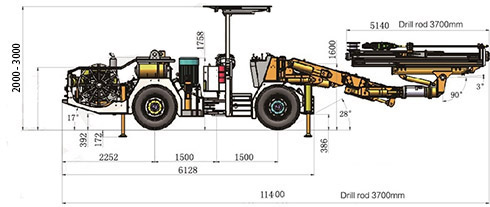

| Cable reel mud clean | Manual | Transport length | 11400 mm |

| Front lights | 6 x 50W LED (4200 lm, 6000 K) | Tramming / drilling width | 1750 mm / 2788 mm |

| Rear lights | 4 x 50W LED (4200 lm, 6000 K) | Tramming / drilling height | 2000 mm / 3000 mm |

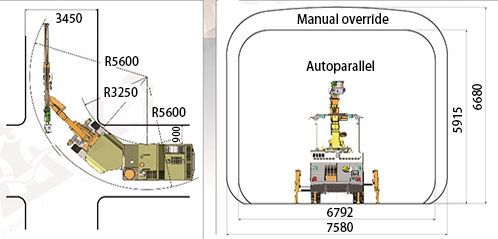

| Percussion hour meters | Optional | Turning width(T-section) | 3450 mm |

| Operator remote control | Optional | Turning radius(Inner/Outter) | R3250 / R5600 mm |

Tailor-made specifications accepted.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.

Split Mountain Machine And Equipment Co.,Ltd. Copyright©splitmountainmachine.com Rights Reserved.